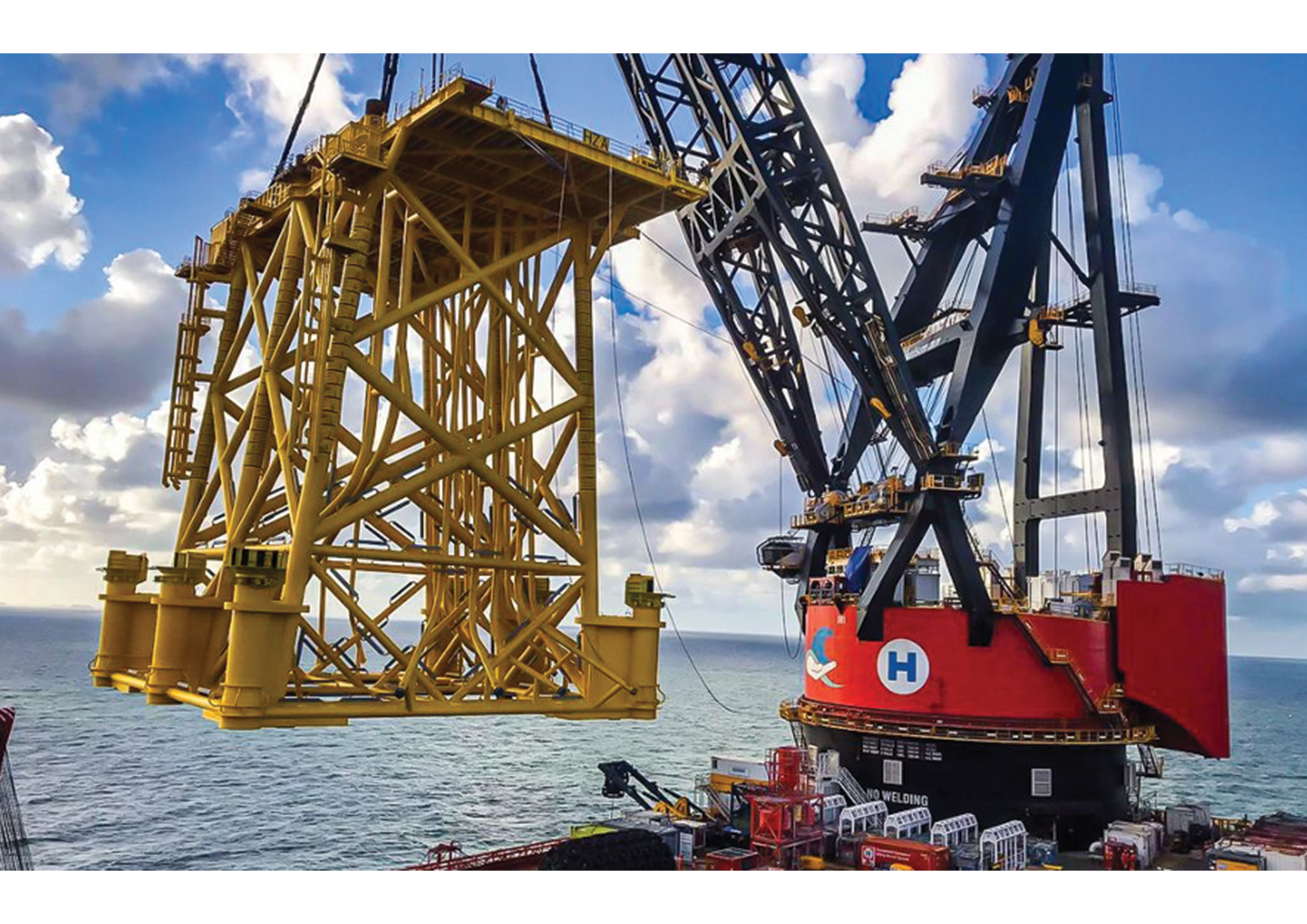

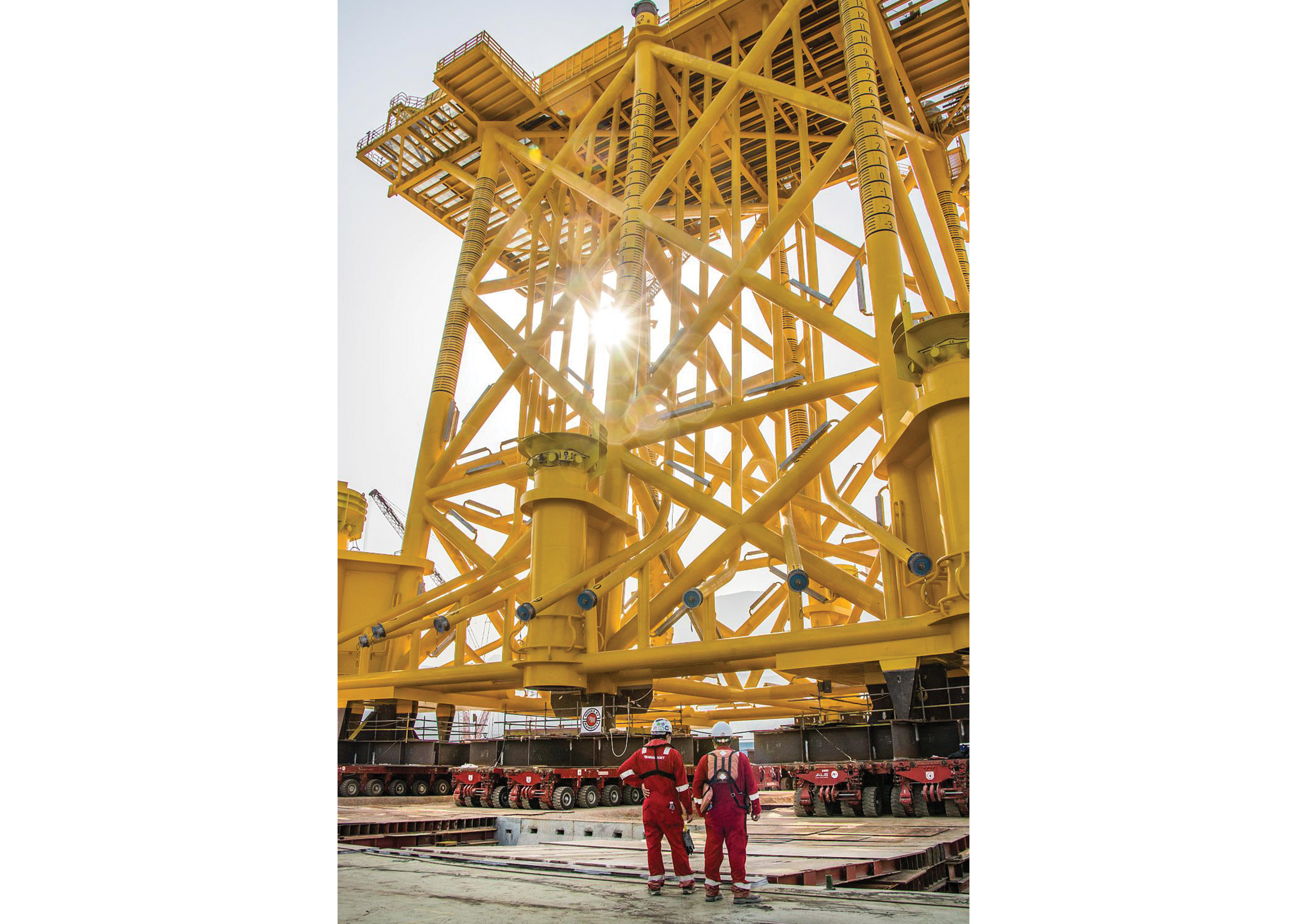

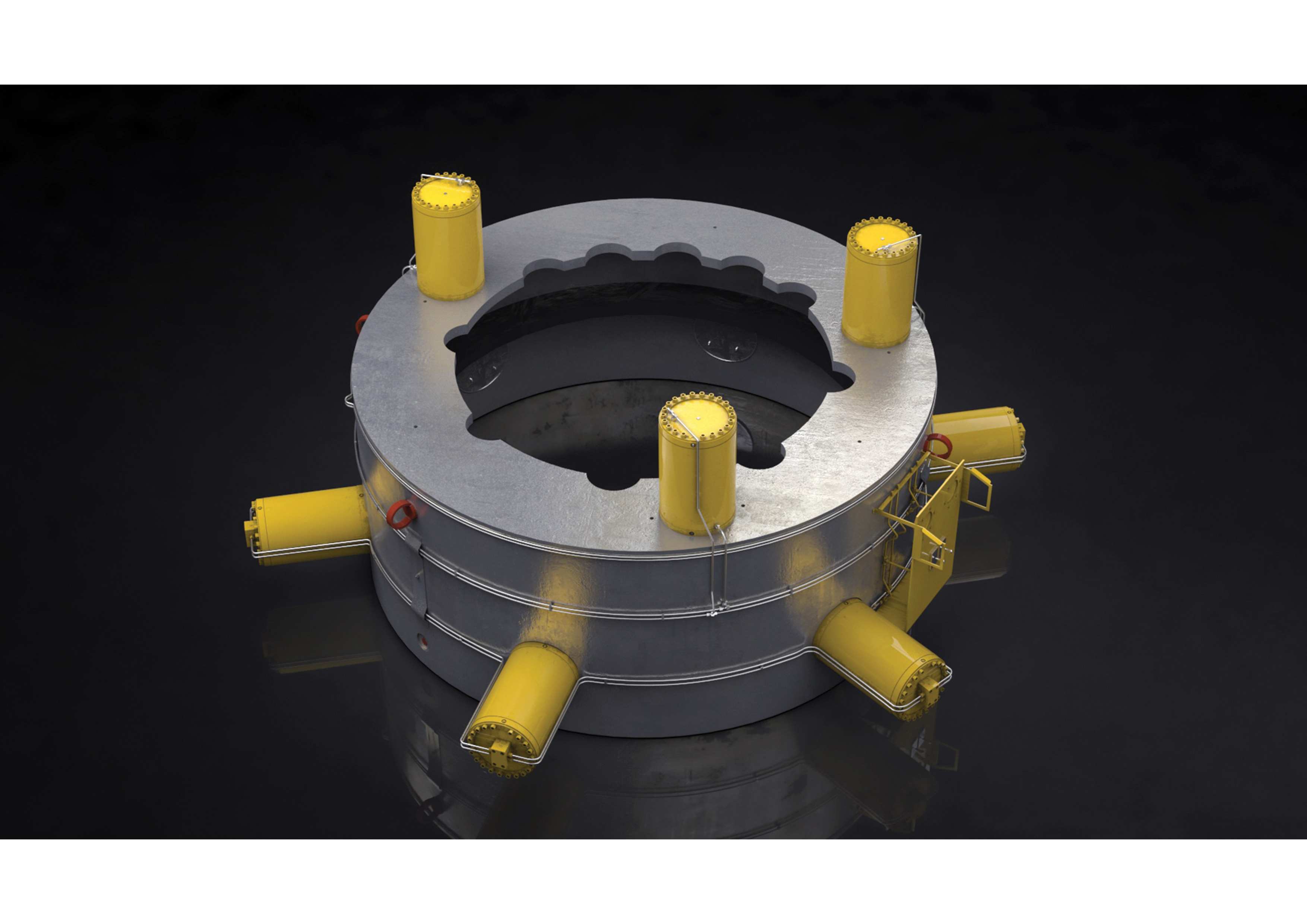

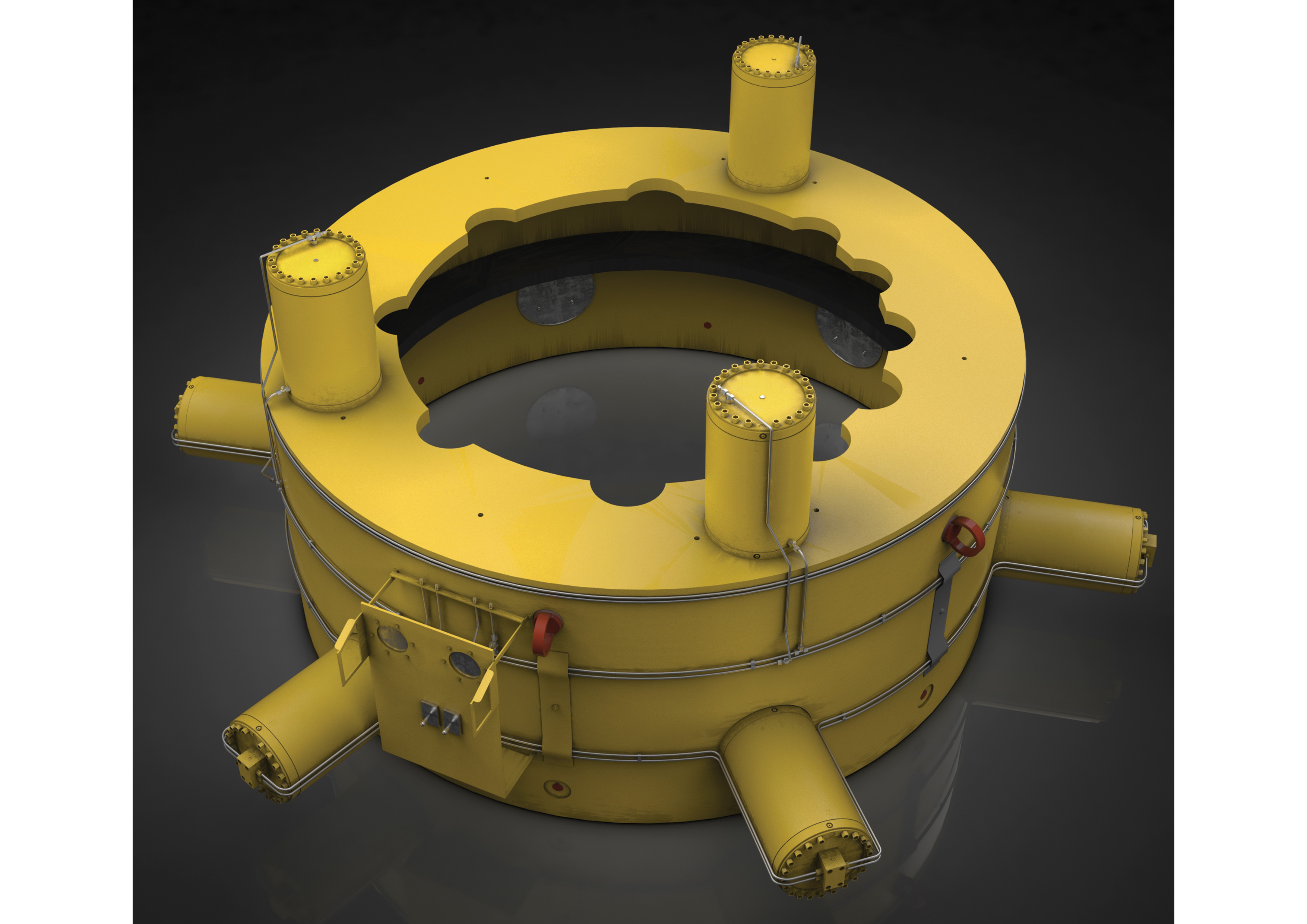

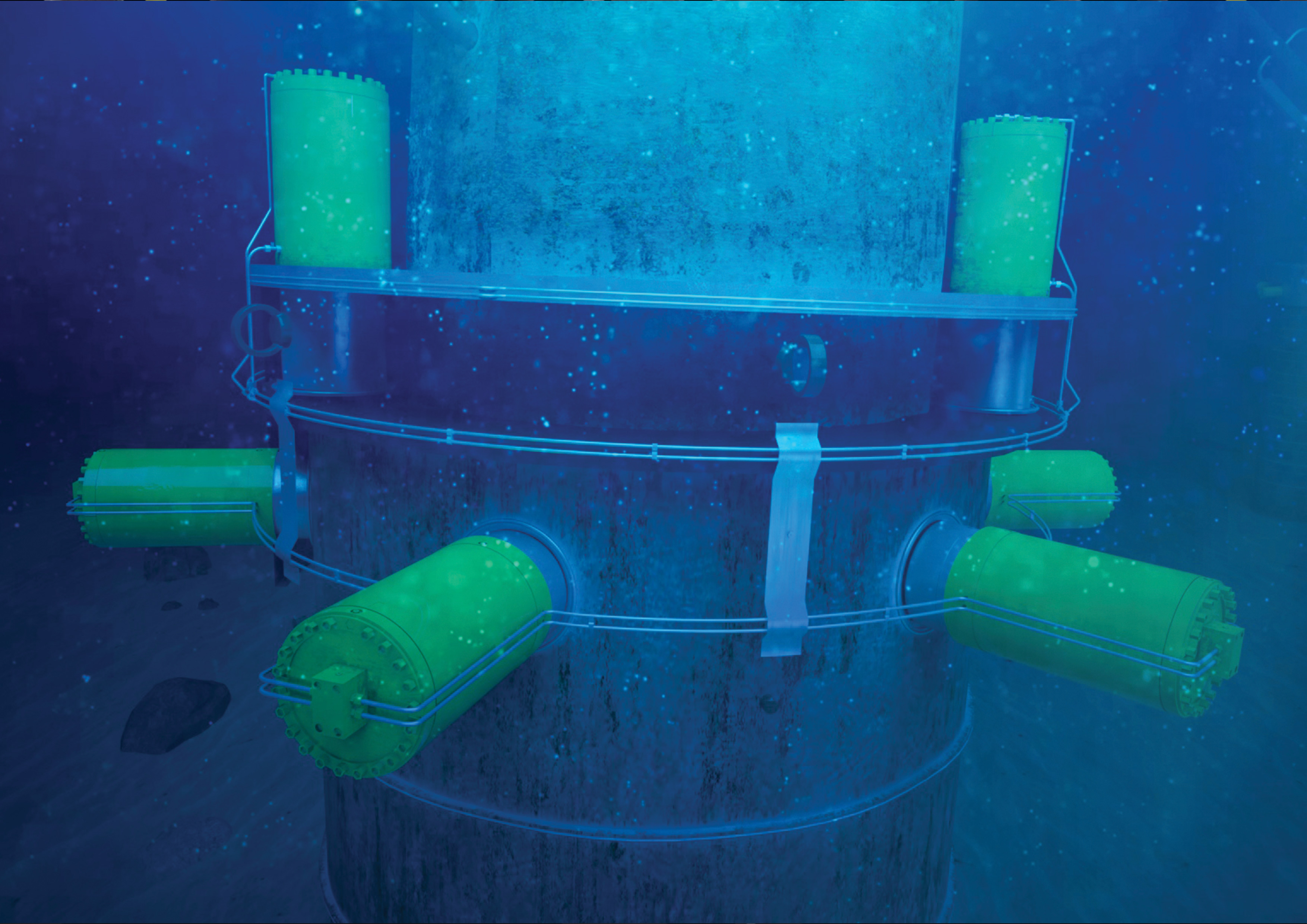

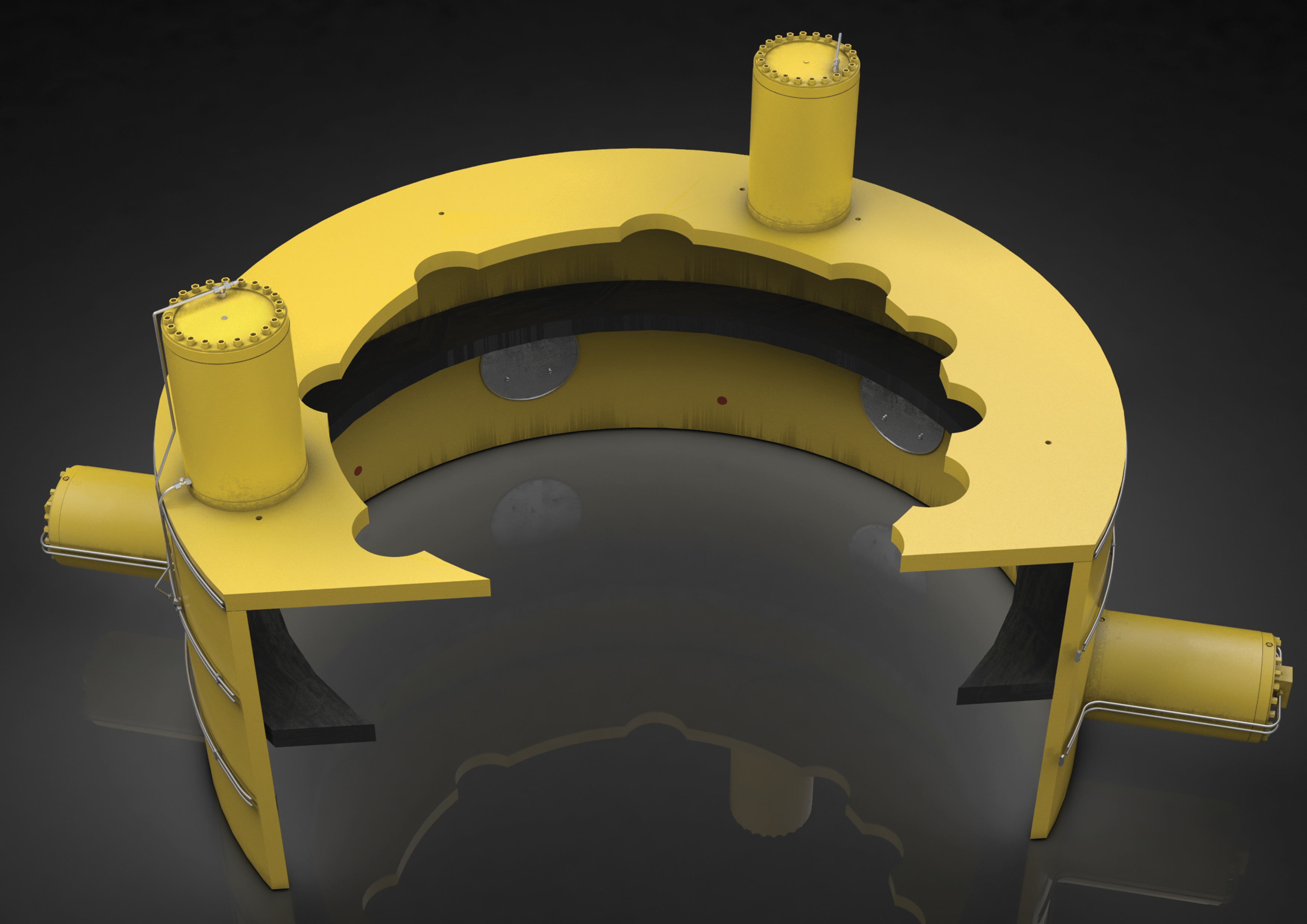

IRM pile grippers assist in leveling during jacket installation and secure the structure both prior to grouting and during the grouting operation. By preventing movement between piles and sleeves, the efficiency of the grouting operation is improved, providing time and cost savings and greater certainty for the grouted connection. Proper leveling of the offshore structures is also one of the important functions of Pile gripper. Moreover, the most vital role of the Pile Grippers is to maintain the status quo of the Piling process if it is interrupted due to bad weather conditions. IRM offers Pile grippers up to 144 inches in diameter and with capacities up to 4500t. The design for larger diameter and capacities are ready for production. Different operational options and hydraulic circuits are also possible. This flexibility enables IRM to provide suitable solutions for every jacket installation.

We provide our supervision services during the Installation and testing of Pile grippers at site and during offshore operations. We have a well-trained & experienced team of Engineers to provide such services to our esteemed clients, for Ease of Installation and operation of the Pile grippers.

Key Attributes

- Custom built grippers as per the specific load requirement.

- Provides stability during the leveling of the jacket in all weather conditions.

- Auxiliary back-up to overcome any contingency during operation.

- All accessories available as per the client’s requirement.