Diaphragm Closures are the most important and critical installation aid for the launching of Offshore Jacket. The critical function of these Diaphragms is to withstand very high hydrostatic pressure while launching the offshore jackets.

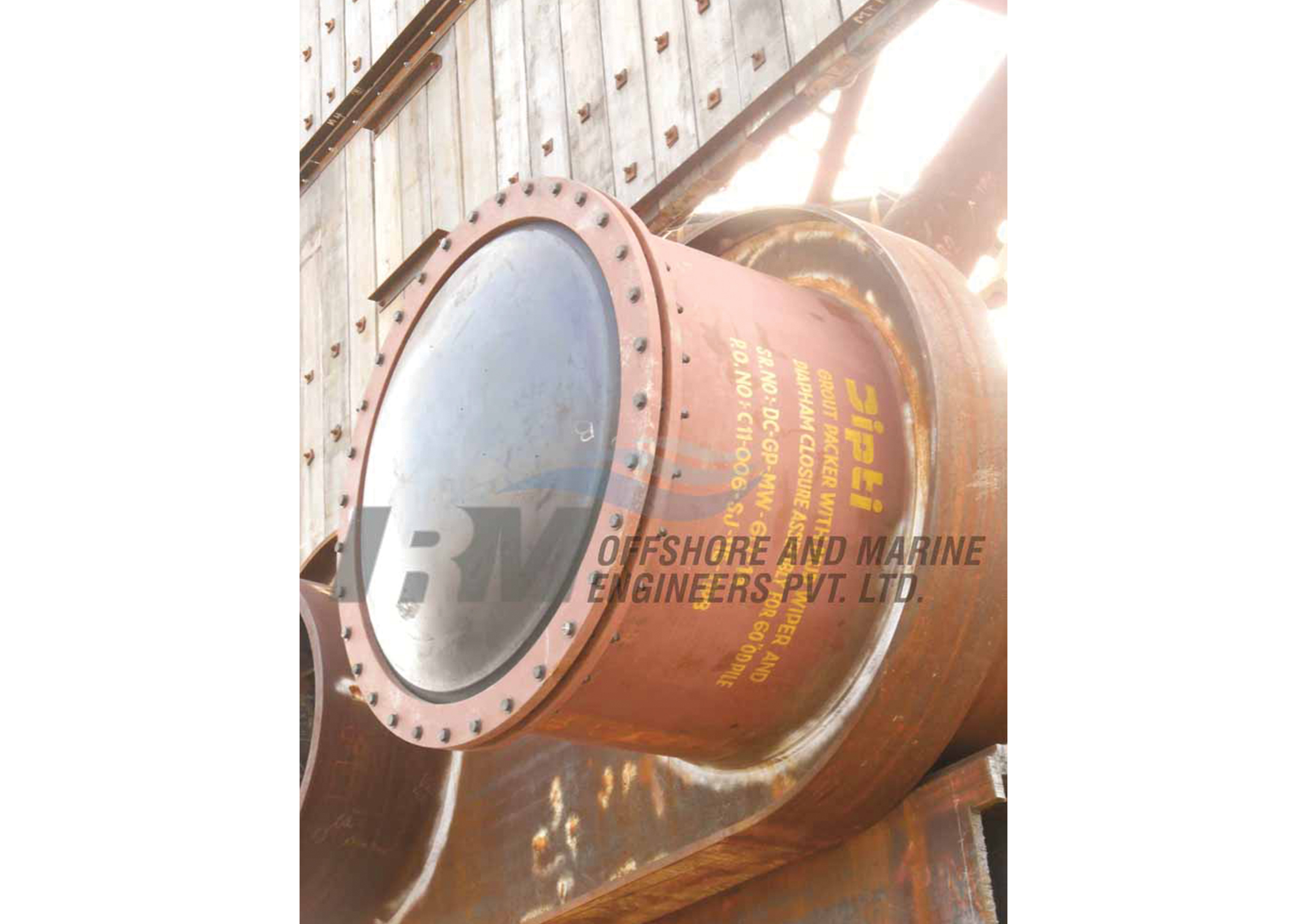

“IRM” Diaphragm Closures are the most important and critical installation aid for the launching of Offshore Jacket. The critical function of these Diaphragms is to withstand very high hydrostatic pressure while launching the offshore jackets. They are specially designed to bear very high water pressure and at the same time to act as a flexible barrier to seal effectively the jacket legs and it enables the platform to float in the sea, facilitating its movement and positioning on site after launching. If the diaphragm fails while launching, the whole jacket sinks into the deep sea and it would be practically very difficult to retrieve the same. The specific purpose of using these flexible diaphragms is, it can be easily ruptured by driving piles or using an integral cutter depending on its design. They are also pressure tested inhouse, for the required pressure. Our “IRM” Diaphragm Closures are having a 100% success rate without any failure and are used in more than 50 platforms worldwide. “IRM” Diaphragm Closures are available in a wide range from 18 inch OD Pile to 144 inch OD Pile. Special sizes can also be developed to suit the client’s requirements.

Product Highlights

- Flanges are shaped to avoid stress concentrations within the diaphragm.

- Made from highly reinforced rubber, designed to withstand the hydrostatic pressure during jacket flooding operations.

- Tested up to 1.5 times the operating pressure.

- ASTM A36 or equivalent material used for the retaining rings/flanges.

“IRM” Diaphragm Closures are available in a wide range from 24 inch OD Pile to 144 inch OD.OD Pile. Customized size can also be developed to suits specific requirements.

- Offshore drilling platforms

- Pile floatation